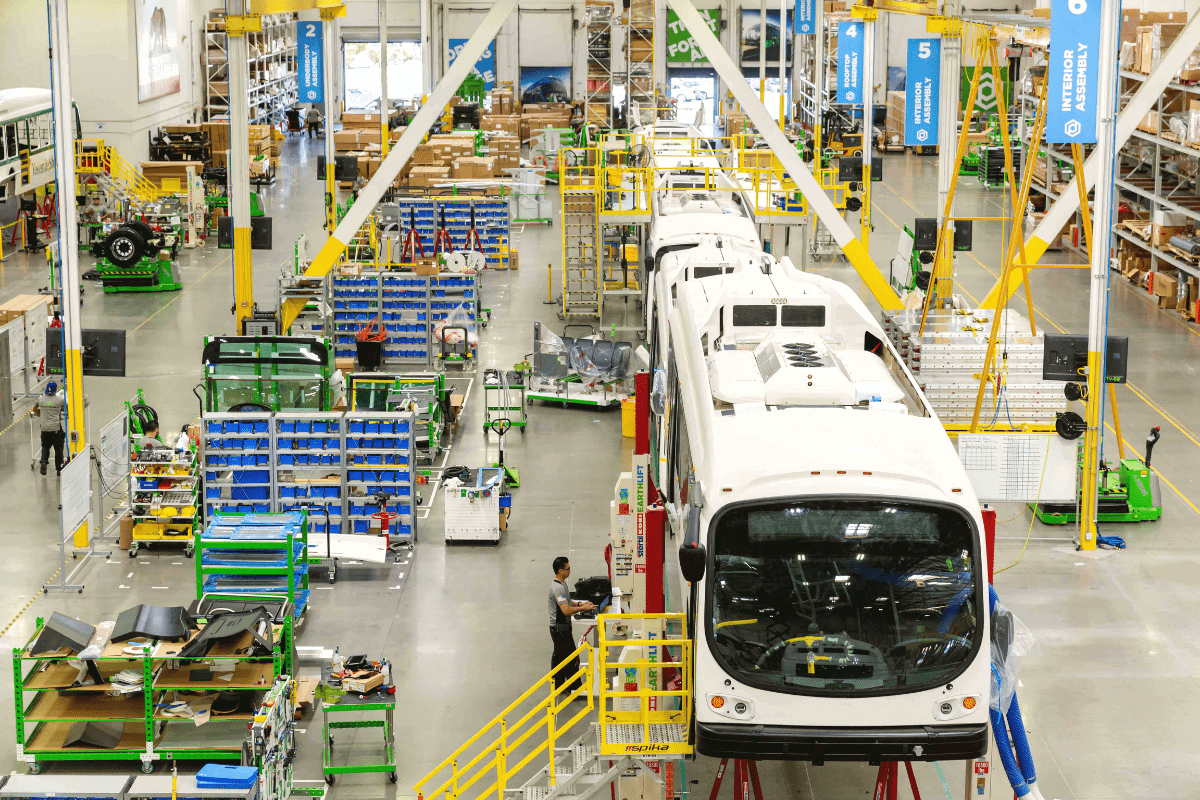

We’re driven by innovation. From lanyard-free access systems for electric bus rooftop maintenance to height adjustable monorail maintenance stands, Spika stands put to the pedal to the metal on safety, productivity, and innovation.

Our access solutions are designed to interface seamlessly with the contours of equipment and adjust to provide access to multiple upper-level task points. That’s why they’re trusted by companies that build and maintain a wide variety of transportation equipment, including electric buses, trailers, RVs, railway and monorail transportation, automobiles, and more.

Our access solutions are designed to interface seamlessly with the contours of equipment and adjust to provide access to multiple upper-level task points. That’s why they’re trusted by companies that build and maintain a wide variety of transportation equipment, including electric buses, trailers, RVs, railway and monorail transportation, automobiles, and more.

THE ZEVOLVE ACCESS SYSTEM

The ZEvolve access system is the only system designed to evolve with a transit agency as it transitions to a zero-emission fleet.

The ZEvolve access system is for evolving fleets with evolving needs. A modular design and height adjustability allow Spika’s stands to adapt to multiple bus sizes as well as unique facility space constraints. This also ensures that they provide gap-free and trip-free access to the bus rooftop without the need for ladders or fall arrest systems.

The electric bus wraparound system was designed in partnership with an electric bus manufacturer, and this intel, combined with Spika’s experience with designing access systems for the aerospace industry, resulted in the ZEvolve access system to provide safe to the bus rooftop during HVAC and battery maintenance.

Spika’s engineering staff has years of experience in designing platforms for electric bus maintenance. Learn more about how we do things The Spika Way.

"Spika can make a complicated custom application that meets the need, and if it doesn’t work, they change it the next day and do a prototype of the development. It helps to get you quickly narrowed in to the right solution... Spika’s design team was just like an extension of my design team.... From initial proposal to design to production, I feel like Spika is a big team player making us successful for our customer."

"We consider Spika to be a partner with KUKA. The Spika design team has been great - they’re flexible and accommodated to all change requests we made throughout the process. Spika platforms are quality, clean, and well put together."

“Customer support has been outstanding. Spika jumps at the opportunity to provide better designed solutions and to accommodate changes without adjusting price. Communication is always excellent and the team is able to work out specific issues and is very transparent on costing and timing.”

"From my end you guys were fantastic to work with. From the first phone calls with you and your team. You provide excellent customer service which is something I really look for when purchasing anything. You were adaptable and flexible, knowledgeable and technical. I really appreciate your continued efforts to ensure we have everything we need."

"Excellent customer service! Provided expert on-site service when issues found due to transport. Very timely and effective correction."

"I have been in helicopter maintenance for the past 35 years. Your stands are superior to everything I've ever worked with since day one! Keep it up!"